- Home

- AAC Information

The AAC materials mainly include sand, fly ash, lime, aluminum powder, aluminum paste, etc.

Sand

Sand is mainly used for providing SiO2 in AAC production line.

| Contents | Superior Quality Product | First Class Product | Quality Product | |

| SiO2 | ≥ | 85.0% | 75% | 65% |

| K2O+Na2O | ≤ | 1.5% | 3.0% | 5.0% |

| Mica | ≤ | 0.5% | 0.5% | 1.0% |

| SO3 | ≤ | 1.0% | 1.0% | 2.0% |

| Silt | ≤ | 3.0% | 5.0% | 8.0% |

Depending on the raw materials, there are mainly two types of AAC concrete blocks: fly ash AAC concrete block and sand ACC block.

Common formulas of AAC concrete blocks summarized by SANKON with many years of manufacturing experience are listed below. You can refer to the formulas listed below when you have chosen a suitable AAC production line

Fly Ash Block| Raw Materials | Unit | Percent |

| Fly Ash | % | 65-70 |

| Cement | % | 6-15 |

| Lime | % | 18-25 |

| Gypsum | % | 3-5 |

| Aluminum Paste (600Kg/m3) | KGS | 0.6 |

| Ratio of water and Material | 0.60-0.75 | |

| Casting Temperature | ℃ | 36-40 |

| Stirring Time for Aluminum Powder | S | 30-40 |

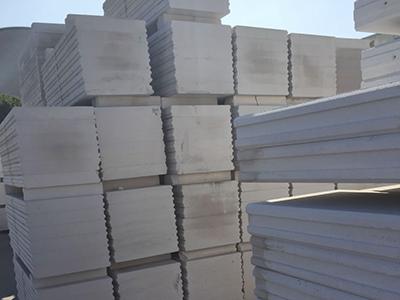

AAC concrete panels are also called autoclaved lightweight concrete (ALC Panels). AAC concrete panels can be used as partition board, cladding panel, roof panel, fireproof plate and so on in concrete construction industry, steel structure industry and civil buildings. ALC partition board can be used as separating wall, indoor compartment wall, bathroom wall, etc. ALC partition board is suitable for hanging objects like, air conditioner, water heater, heating radiator, etc. Therefore, ALC partition board is widely used in hotels, schools, motels, office buildings, etc.

Read More