- Home

- AAC Machines

- Unloading and Packaging Section

- AAC Packaging Machine

AAC Packaging Machine

The AAC packaging machine will pack AAC blocks or panels through the use of polypropylene strapping. There are 3 modes: manual mode, automatic mode and continuous mode. With an easy operation and high speed, the AAC packaging machine is suitable for AAC production lines.

When in operation, the products waiting for packing are placed in the middle of the AAC packaging machine. The AAC packaging machine will first tighten the strap on the products, then compress the strap (under layer), and finally the heater will be put between the two straps and cut the strap.

Features- The stand is made of aluminum alloy. As a result, the AAC packaging machine is lightweight, durable and exceptionally corrosion resistant. Maintenance requiring lubrication oil is not needed.

- The packaging speed is extremely fast, and each AAC packaging machine can work continuously for 16 hours at a time.

Optional Type

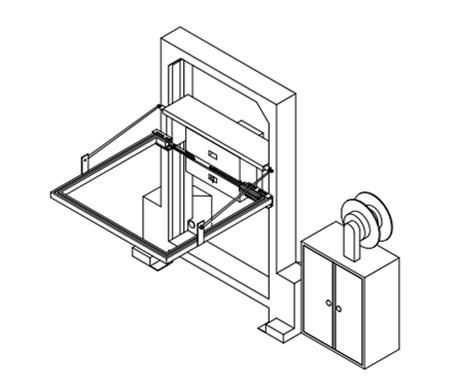

1: Horizontal Packaging MachineApplication: The horizontal packaging machine offers single lane or multi lane horizontal packaging for finished products by foot pedal and automatic control. Strapping is bonded together by a hot melt on the bottom of the finished products.

- Boundary Dimension: L2780×W2110×H2500mm

- Frame Size: W1500mm×H1500mm

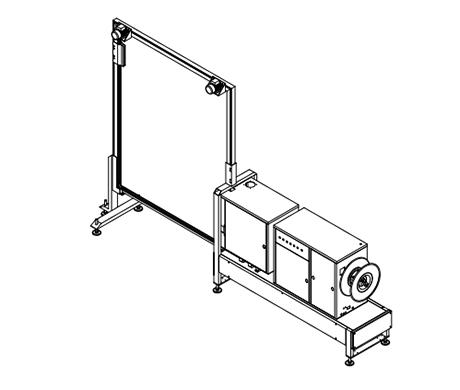

Application: The vertical packaging machine offers single lane or multi lane vertical packaging for finished products by manual control or photoelectric control.

- Boundary Dimension: L3890×W640×H2200mm

- Frame Size: W1500mm×H2200mm

- Power: 380V/50Hz, 3050W/8A

- Air Pressure: 0.4-0.6MPa

- Packaging Speed: ≤15 sec/lane

- Strapping Force: 0-80kg

- Tensile Strength : Max 150 kg

- Operating Noise: ≤75dB(A)

- Ambient Conditions: Relative humidity≤90%, Temperature: 0℃-40℃

- Bottom Bonding : Bonding Surface: ≥90%, Bonding Width: ≥20%, Bonding Error: ≤2mm

- Length of Each Roll: About 2000mm

- Width of Each Roll: (9mm~15mm)±1mm

- Thickness of Each Roll: (0.55mm~1.0mm) ±0.1mm

- Inner Diameter of Strap Reel: 200mm~210mm

- External Diameter of Strap Reel: 400mm~500mm

JIANGSU SANKON BUILDING MATERIALS TECHNOLOGY CO.,LTD.

Add.: No. 31, Xinxi Road, Chuanjiang Town, Xinbei District, Changzhou City, Jiangsu Province

Contact Person: Huang hua (Dale)

Tel.: +86-13915206061

Fax: +86-519-83996829

E-mail: mzq698@163.com