- Home

- AAC Machines

- Unloading and Packaging Section

Unloading and Packaging Section

The autoclaved concrete blocks need to go through several transfer processes:- The transfer trolley will convey the autoclaved concrete blocks out of the concrete curing autoclave.

- The transfer trolley will transfer the autoclaved concrete blocks underneath the lifting appliances. The lifting appliances will then place the autoclaved concrete blocks on the pallet chain conveyor.

- The autoclaved concrete blocks are conveyed to the concrete block separator using the pallet chain conveyor for separating as the set size.

-

- Concrete Block Separator A concrete block separator is used to separate the concrete blocks after autoclaving and before packaging. When the autoclaved concrete blocks are conveyed to the underside of the concrete block separator, the concrete block separator will individually separate the concrete blocks from top to bottom. At the same time, the concrete block separator will remove the substandard products caused by bonding, leading to a stable operation in the packaging process.

After separating, the AAC finished products will be conveyed to the underside of the clamps using the chains or pathway for automatic packaging by the AAC packaging machine.

-

1: Block Packaging

- The clamp will convey the blocks to the pallet or 2 strand chain conveyor for packaging by 0.6m×1.2m or 1.2m×1.2m. The block pallet machine is used to automatically individually send the pallets to the chain conveyor. 2: Panel Packaging

- The panels are conveyed to the chain conveyor using clamps and packaged using the forklift. Workers can attach the panel with no fear of any damage.

-

- AAC Packaging Machine AAC packaging machine will pack AAC blocks or panels through the use of polypropylene strapping. There are 3 modes: manual mode, automatic mode and continuous mode. With an easy operation and high speed, the AAC packaging machine is suitable for AAC production lines. The packaging speed is extremely fast, and each AAC packaging machine can work continuously for 16 hours at a time.

-

- Pallet Chain Conveyor In an AAC production line, a pallet chain conveyor is used to convey the finished products for packaging in the packaging section. There are 2 types available: a single strand chain conveyor and a 2 strand chain conveyor. The single strand chain conveyor is equipped with an angle chain, while the 2 strand chain conveyor is equipped with either a device that can merge 2 stands or a device for pallet recycling.

-

- Block Pallet Machine After completing the manufacturing of AAC blocks, AAC blocks need to be placed on the block pallet for final packaging. To improve the efficiency, we can offer clients a block pallet machine for automatic packaging. When using the block pallet machine, users need to only place the blocks onto the machine, and the block pallet machine will automatically send the pallets individually to the chain conveyor at a set space and speed.

After the blocks are removed, the empty pallet automatically moves forward for cleaning using the cleaning unit. The pallet is then sent back to the overturn table for reuse, using the pallet chain conveyor.

-

- Cleaning Unit

The cleaning unit is installed above the conveyor chain for cleaning the recycling pallets.

The reducer drives the rotation of the steel wire brush for cleaning the hard waste on the pallet.

-

- Industrial Belt Conveyor The industrial belt conveyor, a continuous transport equipment with high conveying capacity, is able to convey products over long distances. Belt conveyors are designed with simple structure and easy maintenance which facilitates programmed control and automatic operation. They are widely used for transporting bulks, powdery or granular goods by continuous or intermittent movement.

-

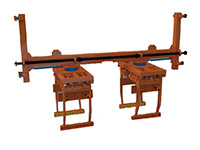

- Block Transfer Device The block transfer device plays an important role in the packaging section of the autoclaved aerated concrete blocks production line, which can combine the blocks with bottom stripped of two molds into the packaging specification without generating bottom friction and move them to the finished product hoist.

-

- Travelling Crane Component During the production of AAC blocks or panels, many travelling crane components such as hoists and clamps are required for transferring aerated concrete cakes or stacking finished AAC products.

Each of these processes is automatically controlled using a PLC system, and requires only 1 or 2 people for monitoring.