- Home

- AAC Machines

- Autoclaved Aerated Concrete Crushing System

- Ball Grinding Mill

Ball Grinding Mill

Application

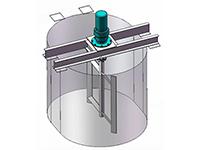

There are two types of ball grinding mill in the AAC production line: dry ball mill and wet ball mill. A ball mill is widely used for material preparation section in AAC production lines.

- After preliminary crushing, lime is further grinded by the ball mill to meet fineness requirements.

- The wet ball mill is mainly used for grinding the sand to meet fineness requirements.

| Model | PE-250×400 | PE-250×750 | PE-250×1000 | |

| Feed End Size (mm) | 250×400 | 250×750 | 250×1000 | |

| Maximum Material Feed Size | (mm) | 210 | 210 | 210 |

| Discharge End Adjustment Range(mm) | 20-60 | 25-60 | 25-60 | |

| Capacity (t/h) | 5-20 | 13-35 | 16-52 | |

| Speed of the Eccentric Shaft (r/min) | 300 | 330 | 330 | |

| Motor Power(Kw) | 15 | 22 | 30 | |

| Total Weight (t) | 2.8 | 5.5 | 7 | |

| Dimension(mm) | 1300×1090×1270 | 1380×1750×1540 | 1560×1950×1390 | |

- The ball mill is equipped with a liner plate and diaphragm. Simple structure and reliable operation are advantages of this ball mill.

- By technological innovation, SANKON prolongs the service life of quick wear parts, and thus enables the ball mill to be easier to maintain and repair.

- The ball mill consumes about 10% less electricity, leading to better energy saving. Besides, the temperature of finished products could be reduced about 20-40℃.

- With higher output and stronger durability, the capacity of ball Mill SONKON manufactured is 15-20% higher than common ball mill.

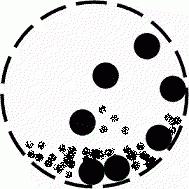

The materials are conveyed evenly into the first chamber which is equipped with stepped liner plate or corrugated liner plate and each size of grinding media (steel ball or cylpebs). As the shell rotates, the balls are lifted up on the rising side of the shell and then they cascade down (or drop down on to the feed), from near the top of the shell. In doing so, the solid particles in between the grinding media and ground are reduced in size by impact.

After finishing coarse grinding in first chamber, the materials would be conveyed to the second chamber which is equipped with flat liner plate and steel balls for further grinding to obtain the powder materials meeting the requirement about fineness.

JIANGSU SANKON BUILDING MATERIALS TECHNOLOGY CO.,LTD.

Add.: No. 31, Xinxi Road, Chuanjiang Town, Xinbei District, Changzhou City, Jiangsu Province

Contact Person: Huang hua (Dale)

Tel.: +86-13915206061

Fax: +86-519-83996829

E-mail: mzq698@163.com